Call Us

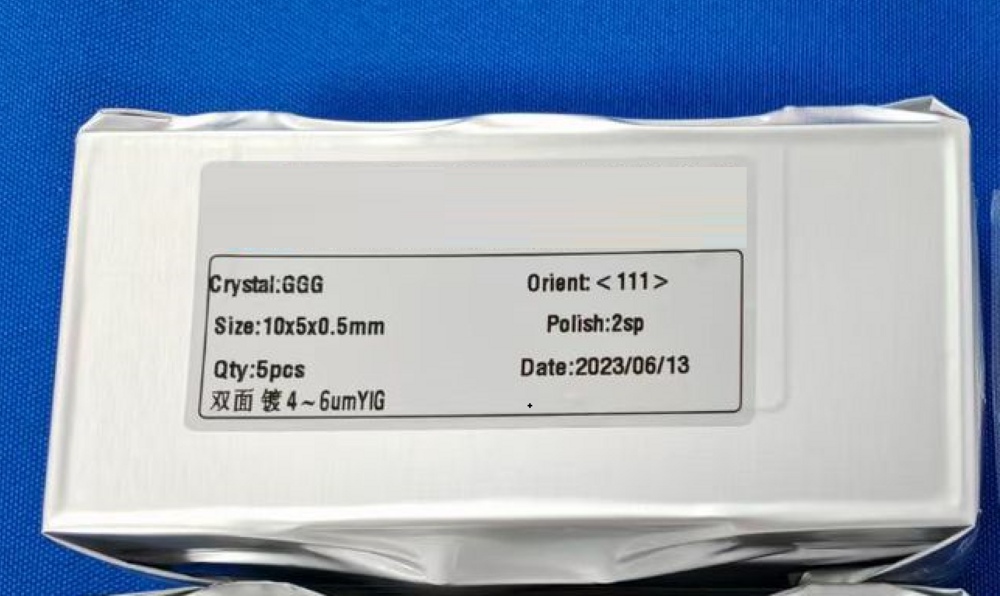

+8615867408815Microwave ferrite with silver coating

Product Details:

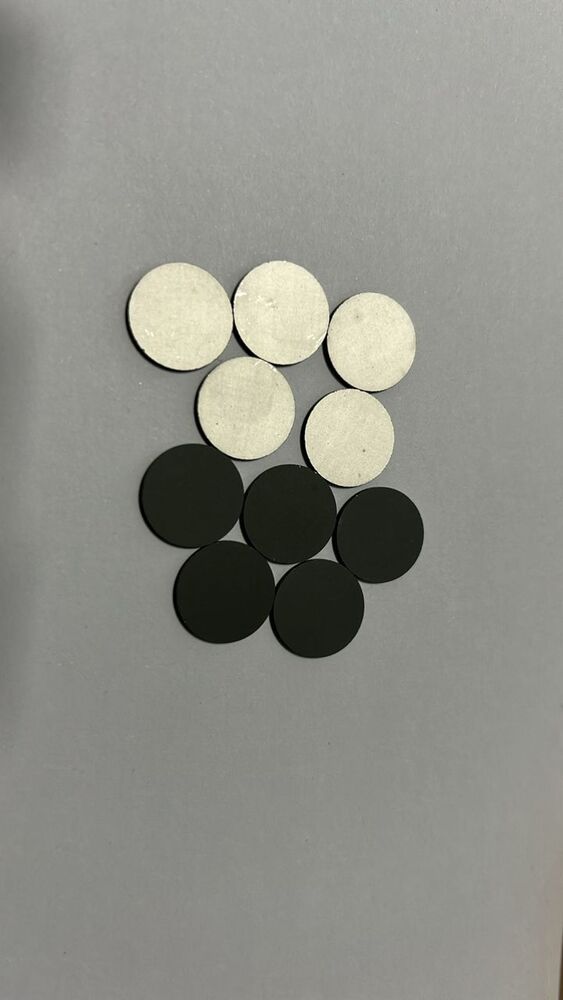

- Composite Microwave ferrite

- Product Type Magnets

- Magnet Category Solenoid Magnets

- Magnet Type Ceramic Magnet

- Shape Sheet

- Color black

- Click to View more

Microwave ferrite with silver coating Price And Quantity

- 50 USD ($)/Piece

- 50.00 - 200.00 USD ($)/Piece

- 1000 Piece

Microwave ferrite with silver coating Product Specifications

- Ceramic Magnet

- black

- Microwave ferrite

- Sheet

- Magnets

- Solenoid Magnets

Microwave ferrite with silver coating Trade Information

- NINGBO

- Paypal, Telegraphic Transfer (T/T), Western Union

- 500000 Piece Per Month

- 25 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Carton Microwave ferrite with silver coating

- Asia, Australia, North America, Eastern Europe, Western Europe

- All India

- REACH and Rohs Microwave ferrite with silver coating

Product Description

Microwave Ferrite Technology, Inc.

Microwave Ferrite Technology, Inc. is a leading manufacturer of microwave ferrite materials for the wireless industry in China. We provide a wide range of products, from high-volume garnets for wireless infrastructure to specialized materials for radar applications.

Applications

Our materials are designed for:

- Above-resonance devices (100 MHz to ~3 GHz)

- Below-resonance devices (1 GHz to 40 GHz or higher)

- High-power and phase-shifting applications

Our Ferrites & Magnetic Materials

We offer a diverse range of advanced ferrite and magnetic materials, including:

- Narrow Linewidth Ferrites: Optimized for high-frequency applications with minimal resonance absorption.

- Aluminum & Aluminum-Gadolinium Substituted Garnets: Enhanced thermal stability for specialized microwave systems.

- Gadolinium-Substituted Garnets: Superior magnetic properties for advanced signal processing.

- Cobalt & Holmium-Doped Garnets: Performance-boosting materials for high-power microwave applications.

- Magnesium Spinels: Low-loss materials ideal for reduced magnetic interference in devices.

- Nickel Spinels: High magnetization and excellent thermal stability.

- Lithium Spinels: Ideal for discrete phase shifters with wide saturation magnetization properties.

- Permanent Magnets: Including ferrite and rare-earth magnets for industrial and scientific applications.

Key Characteristics

Our ferrites are engineered for high-frequency performance:

- High specific electrical resistivity ( > 10 cm), ensuring low dielectric losses (tg: 10 to 10).

- Dielectric permittivity ( 1015).

- Excellent thermal stability across a wide temperature range.

- High activity with minimal bias for optimal nominal parameters.

- Saturation magnetization (4Ms: 4005000 G).

- Narrow resonance linewidth (2H: 0.30.5 Oe for yttrium-iron monocrystals; 31000 Oe for polycrystalline ferrites).

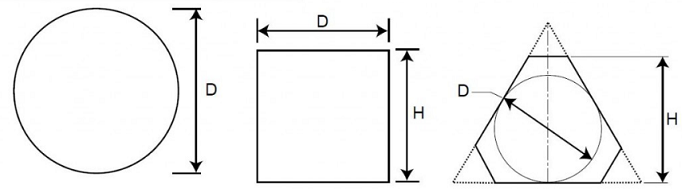

Configurations

Our microwave ferrites and ceramics are available in various shapes and compositions, with precision manufacturing to meet custom requirements.

| Shape | Dimensions | Details |

|---|---|---|

| Disc | Diameter: 1100 mm | Suitable for compact microwave components. |

| Plate | Max: 50.8 x 50.8 mm | Thickness: 0.53 mm, ideal for planar devices. |

| Triangle | Max Diameter: 50 mm | Used in specialized microwave applications. |

| Rod | Max Length: 200 mm | Designed for elongated magnetic components. |

| Composition | Ferrites & Dielectric Materials | Custom compositions available per request. |

| Precision | Tolerance: 0.02 mm | Custom sizes and drawings supported. |

Microwave Ferrite Materials

- Yttrium Iron Garnets (YIG):

- Ideal for high-frequency devices in the lower microwave band.

- Features: Narrow ferromagnetic resonance linewidth, low magnetic losses, high magnetization, and excellent thermal stability.

- Enhanced with Cobalt or Rare-earth ions (Dy, Gd) for improved power stability.

- Spinel-Based Materials:

- Magnesium Spinels: Low coercive field strength, minimal magnetic and dielectric losses, suitable for non-resonance applications.

- Nickel Spinels: Wide magnetization range, high thermal stability, ideal for resonance applications.

- Lithium Spinels: Used in discrete phase shifters, offering low coercive field strength and a wide range of saturation magnetization.

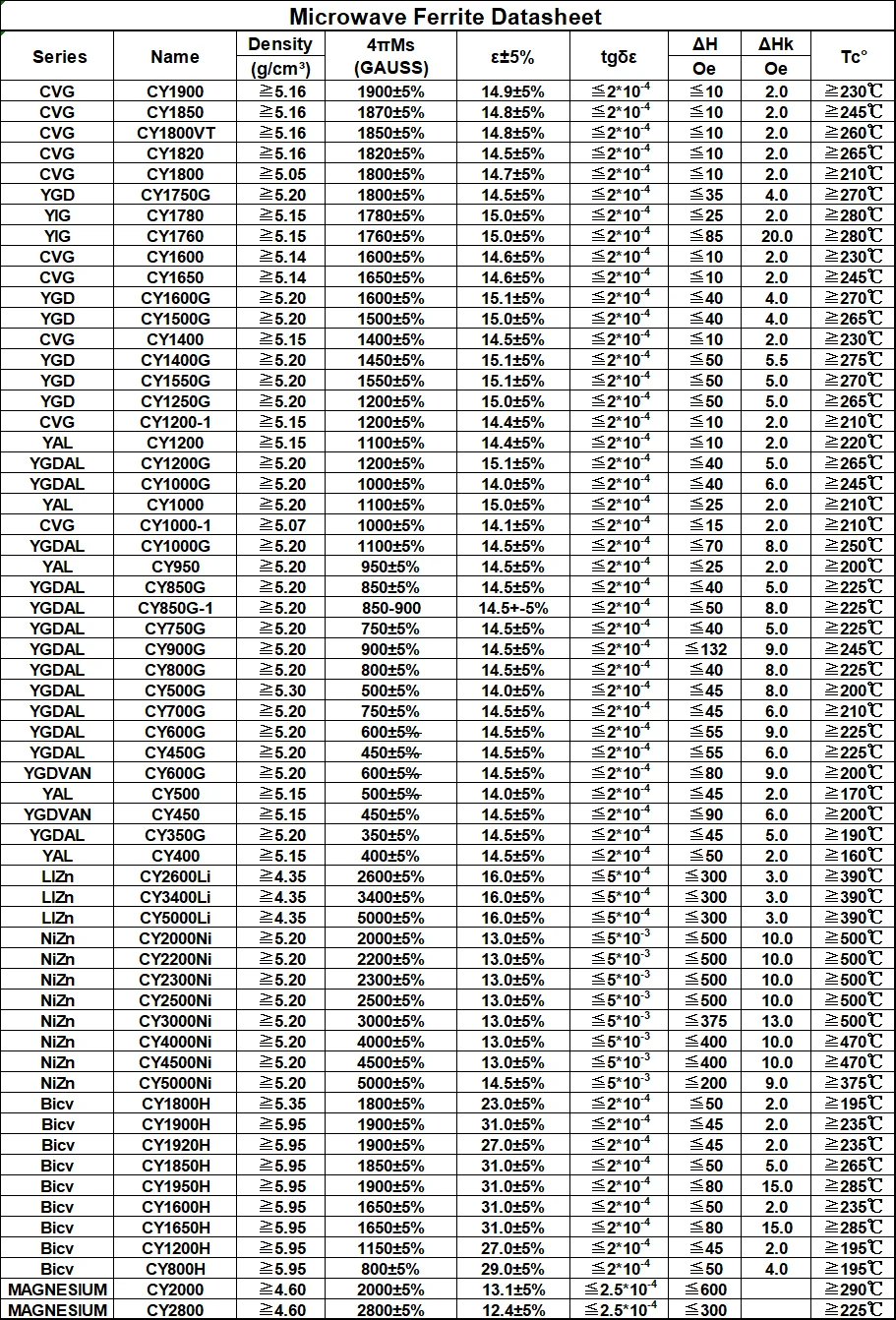

Microwave Ferrite Material Specifications

The table below provides detailed specifications for our microwave ferrite materials, categorized by series. All materials are engineered for high-frequency applications with low losses and excellent thermal stability.

Parameter Definitions

- Density (g/cm): Material density.

- 4Ms (Gauss): Saturation magnetization with 5% tolerance.

- ' 5%: Dielectric permittivity with 5% tolerance.

- tg: Dielectric loss tangent, indicating low dielectric losses.

- H (Oe): Ferromagnetic resonance linewidth, a key indicator of material performance in high-frequency bands.

- Hk (Oe): Anisotropy field linewidth, affecting material stability.

- Tc (C): Curie temperature, indicating the temperature stability range.

Material Series

- Li Ferrite Series: Low magnetic and dielectric losses, high temperature stability, high dielectric coefficient.

- Ni Ferrite Series: Excellent temperature stability, small ferromagnetic resonance linewidth, low dielectric loss.

- Ni Ferrite High-Power Series: Low losses, high surface density, excellent temperature stability.

- General Garnet Series: Low losses, good temperature stability, excellent compatibility.

- Narrow Linewidth Garnet Series: Small resonance linewidth, high stability, excellent surface quality.

- High-Power & Low-Temperature Coefficient Garnet Series: Low losses, high peak power tolerance, temperature stability.

- Microwave High-Q Ferrite Resonator Series: Small resonance linewidth, high-frequency performance, low temperature coefficient (<50 Hz/C), stable properties.

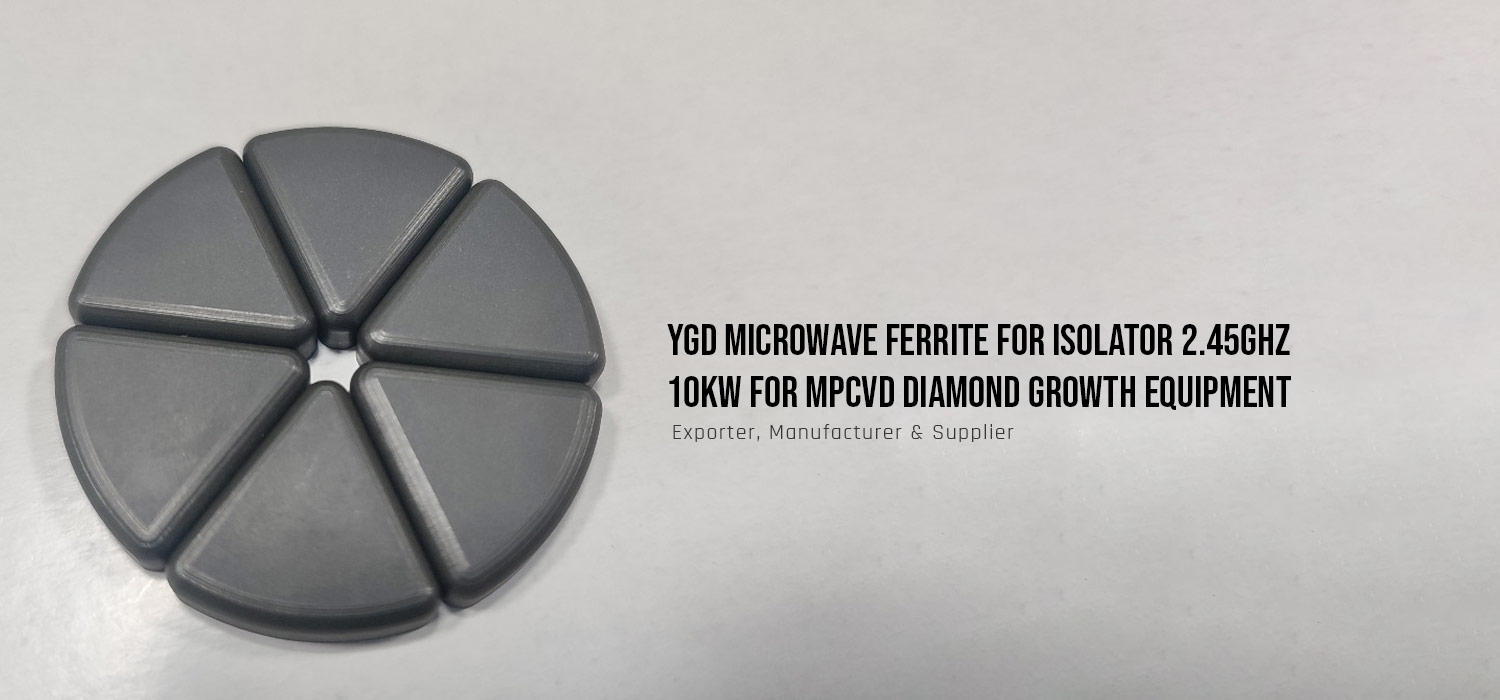

Advantages

- Quality Assurance: Our expert quality control team ensures each ferrite meets stringent standards.

- Versatility: Available in disc, triangular, or custom formats for isolators and circulators across radio-communication frequencies.

- Miniaturization: Ferrite-dielectric composites enable compact isolator/circulator designs with low deltaH (H) for reduced IMD.

Surface Treatment

Protective coatings include Ni-Cu-Ni, Zn, Au, Ag, Sn, Ti, TiN, Cr, and custom options per customer requirements.

Maintenance Guidelines

To maintain magnetic performance and prevent rusting, avoid exposure to:

- Acid or alkali liquids

- Organic solvents, electrolytes, water, or oil

- Hydrogen, chlorine, ammonia, or oxynitride gases

- Radiation or radioactive rays

Applications by Sector

- Garnet & Spinel Ferrites: Space, Defense, Telecommunications

- Ferrite-Dielectric Assemblies: Telecommunications

For more information, please reach out:

Microwave Ferrite Technology, Inc.E-mail: magnet886@gmail.com

WhatsApp: +8615867408815

Website: https://www.microwaveferrite.com

Precision Engineering for Optimal Performance

Our microwave ferrite sheets are crafted with meticulous attention to detail, employing a ceramic magnet core coated in silver for superior electromagnetic characteristics. This composite design reduces signal loss and improves device performance in high-frequency environments. The solenoid magnet category ensures stable field generation, making them indispensable in RF and microwave applications.

Diverse Applications Across Industries

Suitable for telecommunications, radar systems, and scientific research, these ferrite sheets are trusted by engineers and manufacturers worldwide. The sheet shape offers flexible integration into various devices, while the black exterior and silver layer add both functionality and durability. As a leading manufacturer and supplier, we ensure top-tier product consistency and support.

FAQs of Microwave ferrite with silver coating:

Q: How is the silver coating applied to the microwave ferrite sheets?

A: The silver coating is typically applied through an electroplating or sputtering process, creating a thin, uniform conductive layer over the ceramic microwave ferrite sheet. This enhances conductivity and resistance to corrosion while maintaining the underlying magnetic properties.Q: What are the primary uses of microwave ferrite with silver coating?

A: These products are commonly used in high-frequency microwave systems, such as RF isolators, circulators, and filters, where both magnetic and conductive properties are essential for optimal device function.Q: When should I choose a silver-coated ferrite magnet over an uncoated option?

A: Silver-coated ferrite magnets are preferred in applications where enhanced conductivity, better electromagnetic performance, and protection against environmental degradation are requiredespecially in demanding or corrosive environments.Q: Where are these microwave ferrite sheets manufactured and exported?

A: All our microwave ferrite sheets with silver coating are manufactured in China and distributed globally. We export to a wide range of countries, partnering with distributors, suppliers, and traders.Q: What are the benefits of using a solenoid-type microwave ferrite magnet?

A: Solenoid-type ferrite magnets provide stable and uniform magnetic fields, making them highly effective for use in electromagnetic devices that require precision and reliability at microwave frequencies.Q: What is the process for ordering these ferrite sheets as a supplier or distributor?

A: To place an order, contact our sales team with your specifications, including quantity, dimensions, and intended application. We offer tailored solutions and bulk pricing for distributors and suppliers.Q: How does the sheet shape enhance the usage of microwave ferrite magnets?

A: The sheet form allows for easy customization and integration into compact or layered assemblies, making it suitable for various high-frequency electronic devices and systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free